Micro- and Nano- components fabrication and modification

Our technological facilities allow for precise fabrication and modification of components on the micro and nano scale. We carry out both the creation of holes and channels, as well as complex structural modifications, processing various materials according to customer requirements.

Strict IP protection

2 weeks turnaround time

Direct access to engineers

micro- and nanometer-scale precision

THE CHALLENGE OF MINIATURIZATION

The demand for micro- and nano-scale components continues to grow across multiple industries, from advanced optics and photonics to medical devices and precision engineering. These components are not only becoming smaller, but also increasingly complex in structure and functionality. As a result, their development requires highly specialized tools and processes for fabrication, modification, and quality assurance. Meeting these challenges involves mastering techniques that enable precise machining, structural alterations, and detailed microscopic analysis, ensuring performance and reliability at the smallest possible scale.

OUR offer

Our offer includes comprehensive services within prototyping, modification and fabrication of micro- and nano- components, ensuring quality and precision tailored to the specific needs of our clients. We can supply components two-ways:

- Modification of supplied components – modification and processing of components or semifinished products provided by the customer in accordance with the agreed specification and product quality

- Delivery of a finished component – purchase of raw materials based on client’s guidelines, modification and processing according to the agreed specifications and quality standards.

Explore our methods

Prototyping

Our offer includes:

- Modification of supplied components – modification and processing of components or semi-finished products provided by the customer in accordance with the agreed specification and product quality.

- Delivery of a finished component – purchase of raw materials based on client’s guidelines, modification and processing according to the agreed specifications and quality standards

Our offer includes comprehensive services within the modification and production of micro- and nanocomponents, ensuring quality and precision tailored to the specific needs of our clients.

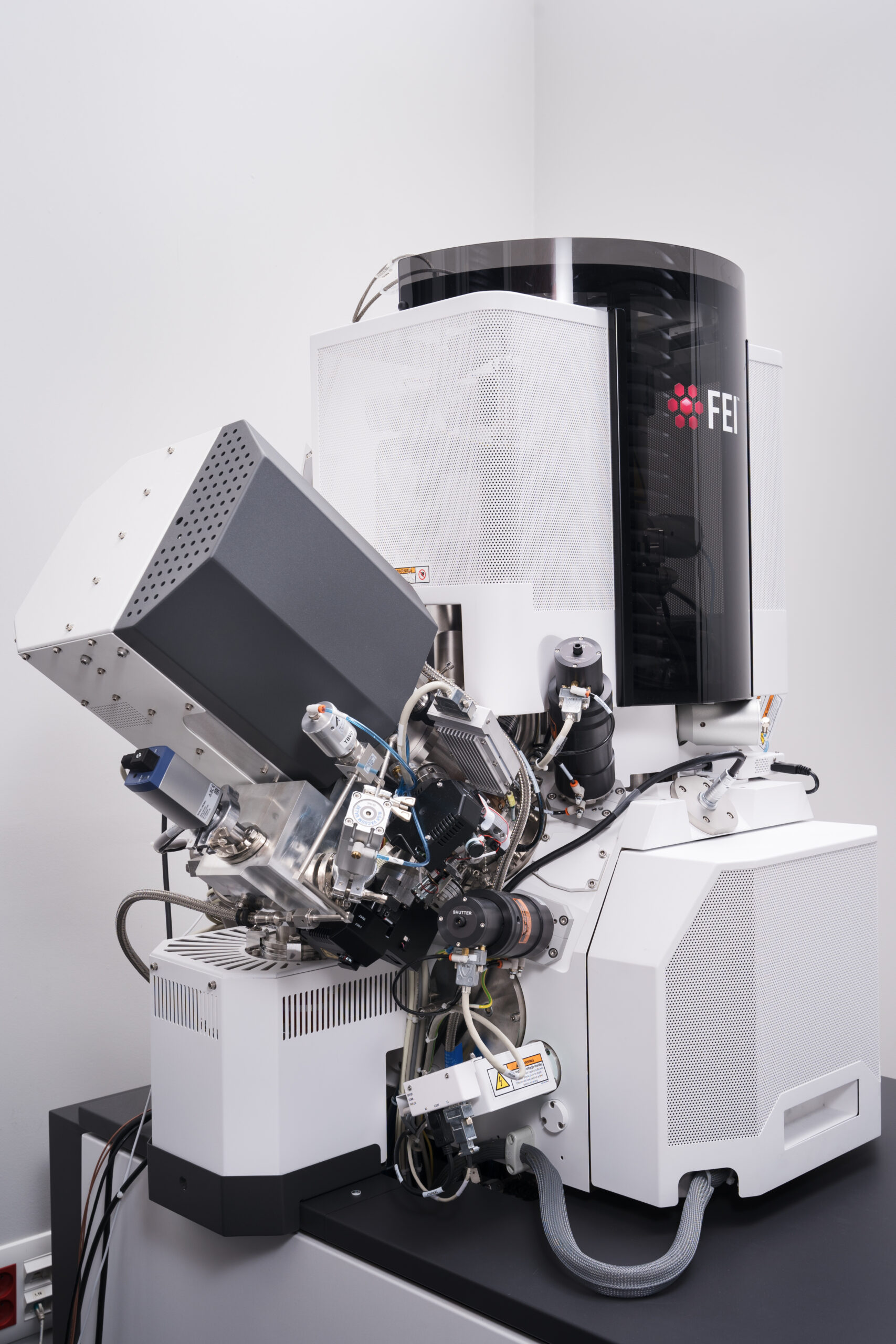

GA - FIB

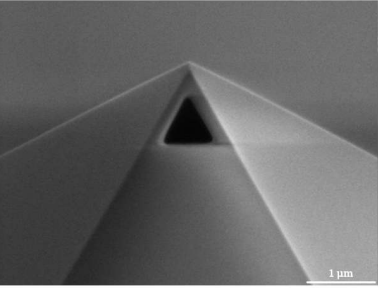

- Ultra-high precision and resolution for fine milling and polishing — ideal for nanoscale features

- Optimized for small volumes: controlled, repeatable material removal with clean edges

- Best when surface quality matters more than speed

Focused Gallium Ion Beam (Ga-FIB) is an advanced technique that uses a focused ion beam for precise modification and fabrication of structures at the nanometric scale. Unlike traditional laser or mechanical processing, the FIB method allows for extremely controlled material removal or deposition with greater accuracy.

XE - PFIB

- Maximum throughput for rapid prototyping, with beam currents up to the microamp range

- Inert Xenon ions minimizes contamination risk compared with Ga ions, preserving material integrity

- Slightly larger spot size at high currents — unbeatable for bulk removal and pre-finish sample preperation

- Stitchless large-area patterning and high-throughput fabrication of uniform modification arrays

Focused Xenon Plasma Beam (Xe-PFIB) enables faster work with materials such as gallium or aluminum, as it prevents gallium ion implantation, avoiding changes in elemental composition and properties.

IR - LASER

- Capability to process any solid material, removing it only where intended (layer-by-layer processing)

- 5-axis beam positioning (x, y, z, α, β), enabling the creation of complex geometries

- Ability to achieve vertical sidewalls with a maximum structure aspect ratio of 10:1

A femtosecond laser is an advanced ultrashort-pulse laser that emits light pulses lasting only a few hundred femtoseconds. Such short pulses allow for extremely precise material processing with minimal thermal impact.

UV - LASER

- Capability to process any solid material, removing it only where intended (layer-by-layer processing)

- Minimum modification size of ~1 µm

- Processing accuracy <100 nm

- Capability for precision processing of optical materials while preserving surface quality

A femtosecond laser is an advanced ultrashort-pulse laser that emits light pulses lasting only a few hundred femtoseconds. Such short pulses allow for extremely precise material processing with minimal thermal impact.

Combining methods

Our equipment and expertise allow us to combine methods, utilizing both techniques to create more complex and demanding structures with different levels of component accuracy.

A DEMO DAY ON YOUR OWN SAMPLES AND CREATE YOUR RESEARCH PLAN WITH US

The best way to verify our methods is to see the results from your own sample. Apply for a free demonstration session and see the quality of our work