Material Research

We conduct detailed analyses of material properties and structures. Our research allows for the detection of hidden defects, determination of composition and quality of materials, and assessment of their suitability for further stages of the design or production process.

Strict IP protection

2 weeks turnaround time

Direct access to engineers

Possibility to participate in research (online/on-site)

THE CHALLENGE OF MATERIAL CHARACTERIZATION

As modern technologies evolve, materials used in advanced manufacturing, microelectronics, and photonics become increasingly complex and diverse. Their performance often depends on microscopic structural features invisible to the naked eye. This creates the need for precise and comprehensive material research – capable of detecting hidden defects, analyzing chemical composition, and understanding internal structures.

Detailed characterization is essential for ensuring reliability, improving process efficiency, and enabling innovation in design and production, making material research a cornerstone of progress in high-tech industries.

Micro-Computed Tomography (uCT)

µCT is a versatile tool used across many fields, including materials research, advanced manufacturing, and quality control. It provides valuable insights into:

- Microstructural integrity – detection of pores, cracks, delaminations, and inclusions,

- Geometrical verification – precise 3D measurements of internal and external features,

- Process optimization – evaluation of additive manufacturing, laser micromachining, or molding processes,

- Material characterization – analysis of density variations, fiber orientation, or phase distribution.

The technique can be applied to a wide range of materials – from metals and ceramics to polymers, composites, and porous structures.

Micro-Computed Tomography (µCT) is a non-destructive 3D imaging technique that reveals the internal structure of materials with micrometer or even submicrometer resolution. It enables visualization and quantitative analysis of geometry, porosity, cracks, inclusions, and other internal features – all without cutting or damaging the sample.

Confocal microscopy

Confocal microscopy supports a wide range of applications, including surface quality assessment, topography measurement, failure analysis, and process verification in areas such as additive manufacturing, microfabrication, and thin-film technologies.

By combining optical precision with true 3D reconstruction, confocal microscopy enables accurate, repeatable, and non-destructive characterization of metals, ceramics, polymers, and semiconductor materials — delivering insights essential for improving performance, reliability, and process control.

Confocal microscopy provides high-resolution 3D imaging and precise depth profiling, enabling detailed inspection of material surfaces and subsurface structures without physical contact. The technique offers exceptional contrast and clarity, making it ideal for analyzing micro- and nanoscale features critical to advanced materials research and precision manufacturing.

Metallographic Laboratory Setup

- Microstructure Observation – Our laboratory enables in-depth imaging and surface evaluation using a variety of advanced techniques, including laser confocal microscopy and optical microscopy. These methods provide detailed information about surface quality and microstructure morphology across multiple scales — from the nano to the macro level.

- Hardness Measurement – The fully automated NEMESIS 5100G2/A Hardness Tester allows for measurements using Brinell, Vickers, and Rockwell methods within a load range of 0.010 kgf to 250 kgf.

- Chemical Composition Analysis – Chemical composition is evaluated using Glow Discharge Optical Emission Spectroscopy (GDS OES), which enables accurate determination of elemental content and layer depth profiling. This technique allows verification of material conformity with relevant standards, certificates, and specifications.

Our advanced metallographic laboratory is equipped to support comprehensive material characterization — from sample preparation to detailed structural and compositional analysis. Using state-of-the-art instruments and methodologies, we deliver precise insights into the properties and performance of metallic materials.

SEM Observations

SEM detects different types of electron signals, each delivering unique insights:

- Secondary Electrons (SE) – reveal fine surface topography, allowing precise examination of textures, cracks, voids, and contaminants,

- Backscattered Electrons (BSE) – provide compositional contrast, making it possible to distinguish between materials and identify structural variations such as inclusions or diffusion zones,

- Energy-Dispersive X-ray Spectroscopy (EDS) – enables elemental composition analysis, helping verify material integrity and detect impurities or unwanted elements.

This versatility makes SEM an indispensable tool for failure analysis, process optimization, and material characterization. It offers a clear, high-detail view into structures ranging from metals and ceramics to polymers, composites, and semiconductor materials, ensuring reliability, performance, and control at the microscale.

Scanning Electron Microscopy (SEM) provides exceptional imaging capabilities for detailed surface and subsurface analysis of materials. By combining high resolution, versatile signal detection, and non-destructive operation, SEM enables comprehensive evaluation of microstructures, defects, and material composition — supporting both research and quality assurance in advanced manufacturing.

EDS

EDS provides qualitative and quantitative information about the elements present in a sample, making it an essential tool for failure analysis, material verification, and contamination detection. The technique delivers fast, accurate results without damaging the specimen — ideal for research, development, and quality control applications across metals, ceramics, polymers, and composites.

Energy-Dispersive X-ray Spectroscopy (EDS) enables precise elemental analysis of materials at the micro- and nanoscale. Integrated with Scanning Electron Microscopy (SEM), it identifies the chemical composition of individual phases, inclusions, and contaminants directly within the imaged area.

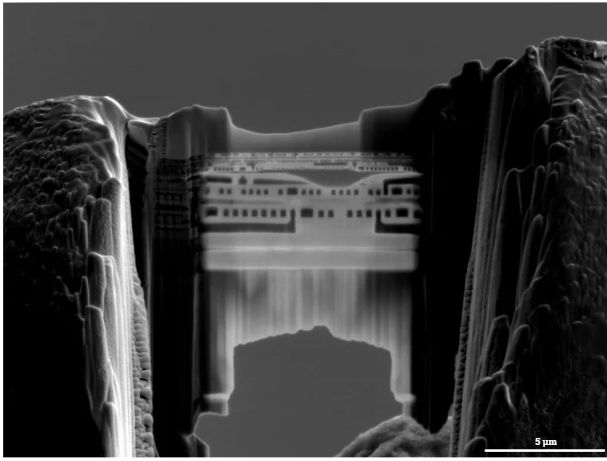

FIB cross-sections

The local cross-section technique does not cause any mechanical damage to the coating that occurs during conventional metallographic preparation and could not be interpreted as defects in the coating.

COATING THICKNESS MEASUREMENTS

The thickness of the layer is often a critical parameter that influences the usability of the manufactured elements. For special coatings made of precious and semi-precious metals, their thickness must be strictly controlled within certain intervals.

The offered layer thickness measurement allows a precise determination of the layer thickness at the location specified by the customer. The high-resolution imaging mode allows the measurement of multilayer coatings with a thickness of a few nanometers.

IDENTIFICATION OF COATING DEFECTS

Delaminations, cracks, impurities, porosities, wear or spalls are examples of effects which can be observed on the surface and cross-section of the tested elements. Each of these defectives is the result of a factor whose identification is our main goal.

Once armed with such information, engineers and researchers can introduce quality improvements at the earliest stages of defect formation.

With our Xe-PFIB and Ga-FIB devices, local cross-sections can be produced with a focused ion beam that allows selective material extraction and the creation of crosssections with a roughness of up to one nanometer. After removing the material and ion polishing it is possible to create a SEM image and a map of the element surface of the blend.

Laser and FIB cross-sections

- Rapid Bulk Removal – the femtosecond laser efficiently removes large material volumes, dramatically accelerating the cross-sectioning process compared to FIB alone,

- Non-Thermal Ablation – ultrashort laser pulses minimize heat-affected zones, preserving the integrity of nearby features and delicate microstructures,

- Precision Finishing – FIB provides controlled polishing for the final steps, delivering smooth, high-quality cross-sections ready for SEM or TEM inspection.

This complementary workflow ensures high throughput, minimal damage, and exceptional precision, making it ideal for applications in semiconductor analysis, materials research, and advanced process development.

The combination of femtosecond laser ablation and Focused Ion Beam (FIB) polishing offers a powerful solution for fast and precise cross-sectioning of materials and microelectronic structures. This hybrid approach merges the speed and efficiency of laser processing with the nanometer-scale precision of FIB, enabling high-quality sample preparation for detailed structural and failure analysis.

TEM lamellae preparation

Precise sample preparation is essential for high-quality Transmission Electron Microscopy (TEM) analysis. Using Gallium Focused Ion Beam (Ga-FIB) and Xenon Plasma Focused Ion Beam (Xe-PFIB) systems, thin TEM lamellae are prepared with nanometer precision and minimal damage. These methods allow site-specific cross-sectioning of regions of interest, even within complex or multilayered materials. The combination of high milling accuracy and controlled polishing ensures optimal sample quality for atomic-scale imaging and analytical techniques.

TEM observations

Transmission Electron Microscopy (TEM) provides atomic-resolution imaging and compositional and crystallographic analysis of materials. Through Ultra-High Resolution TEM (UHRTEM), internal structures, interfaces, and defects can be directly visualized. Integrated Energy-Dispersive X-ray Spectroscopy (EDS) enables elemental mapping, while Selected Area Electron Diffraction (SAED) reveals crystal orientation and phase information. Together, these methods deliver a comprehensive understanding of material structure, supporting failure analysis, process optimization, and advanced materials research.

3D reconstruction Xe-PFIB

With our advanced devices and professional software, we are able to perform cross-sections series and then record them in a micro- and nanometric scale. The results of this process can then be transformed into high-quality 3D reconstructions of the sample microstructure. This enables the structural changes verification and their statistical analysis within a certain sample volume

Atomic Force Microscopy

EDS provides qualitative and quantitative information about the elements present in a sample, making it an essential tool for failure analysis, material verification, and contamination detection. The technique delivers fast, accurate results without damaging the specimen — ideal for research, development, and quality control applications across metals, ceramics, polymers, and composites.

Atomic Force Microscopy provides high-resolution, three-dimensional imaging of material surfaces at the nanometer scale. The technique enables precise characterization of surface topography, roughness, and mechanical properties such as stiffness or adhesion. AFM allows the observation of structural details beyond the limits of optical microscopy, offering valuable insights into the morphology and surface phenomena of metallic and non-metallic materials.

A DEMO DAY ON YOUR OWN SAMPLES AND CREATE YOUR RESEARCH PLAN WITH US

The best way to verify our methods is to see the results from your own sample. Apply for a free demonstration session and see the quality of our work